6,272 reads

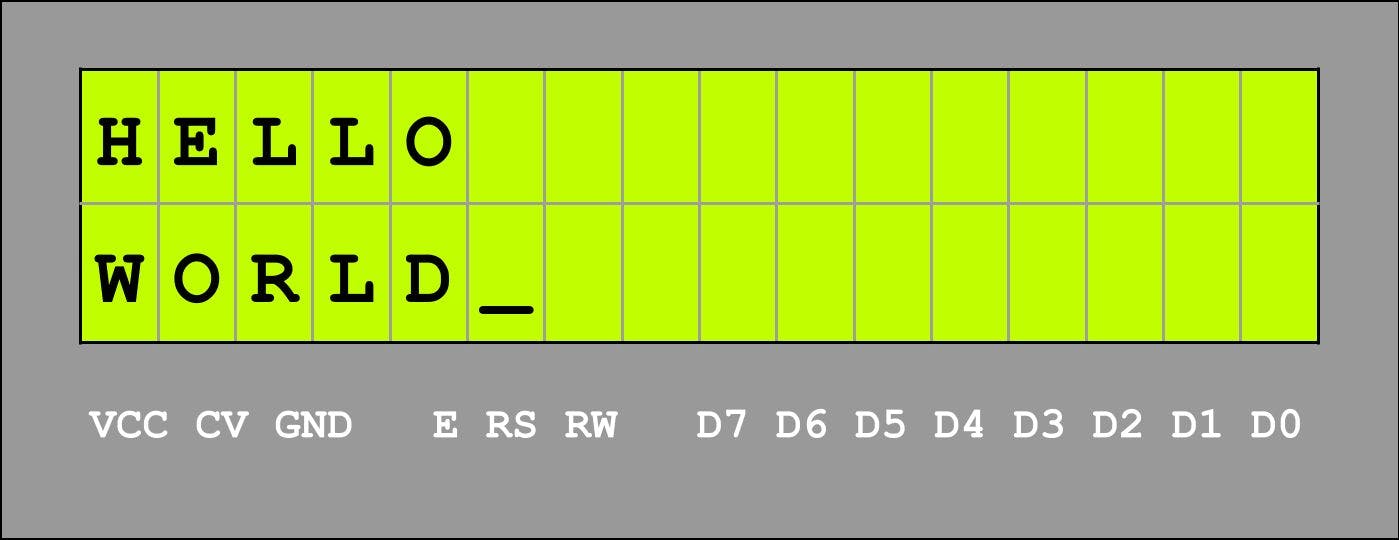

How to Interface the 8051 MCU with an LCD Display

by

January 21st, 2022

Audio Presented by

Freshman at Yale majoring in electrical engineering. Interested in neuroscience, CS, math, and everything in-between!

About Author

Freshman at Yale majoring in electrical engineering. Interested in neuroscience, CS, math, and everything in-between!