31,098 reads

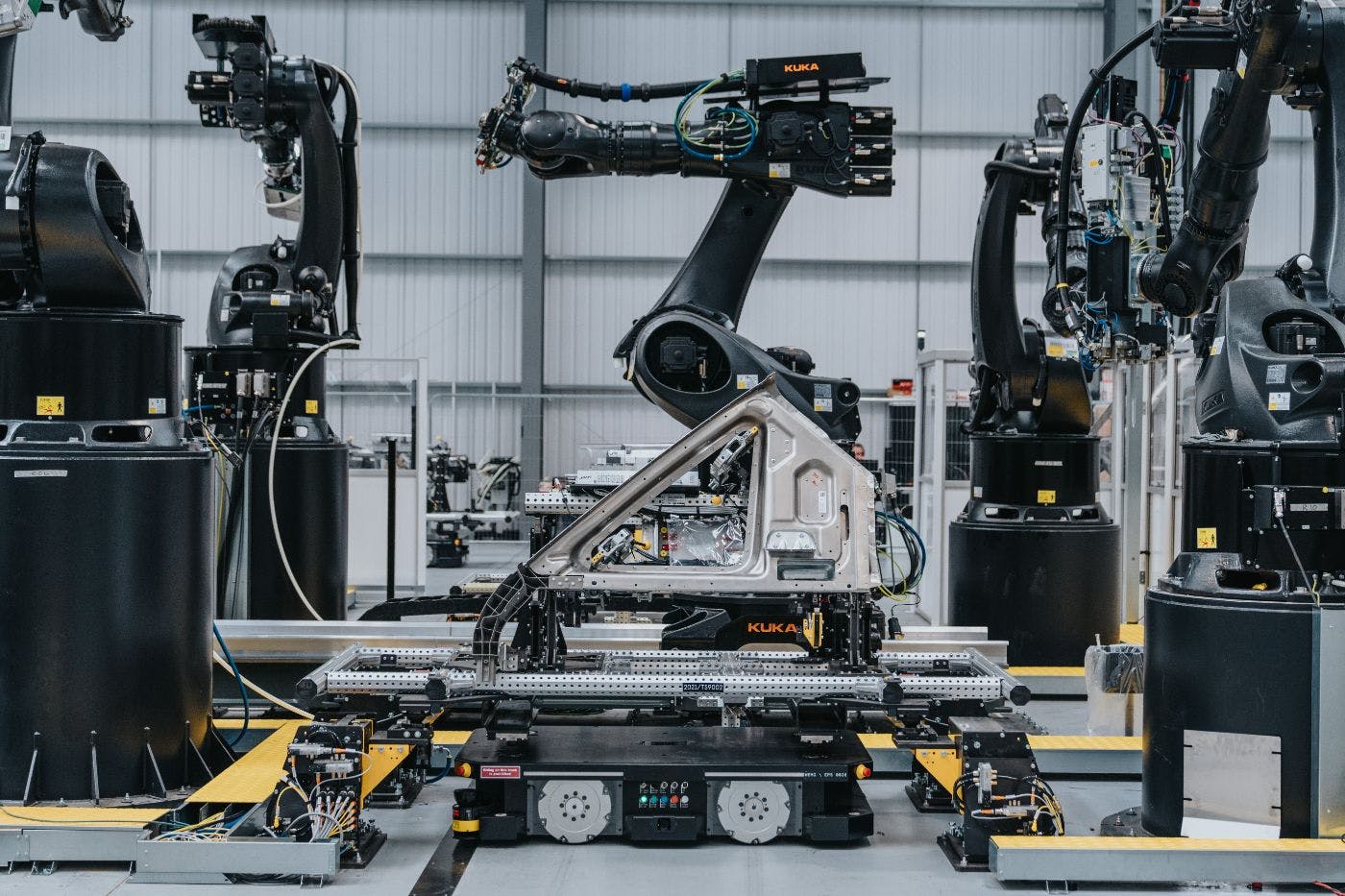

Implementation of Mobile Robots for an Autonomous Scalable Smart Factory

by

March 9th, 2023

Audio Presented by

I’m creating a new way of manufacturing - an autonomous scalable, software-defined, product-agnostic robotic factory

About Author

I’m creating a new way of manufacturing - an autonomous scalable, software-defined, product-agnostic robotic factory