2,637 reads

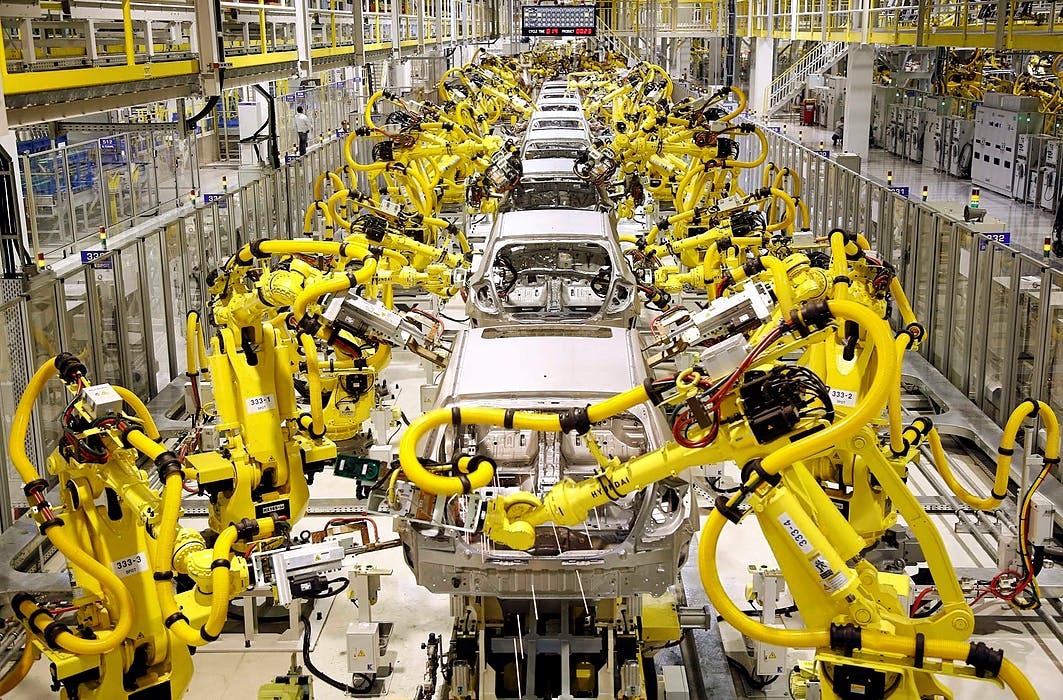

Five Successful AI and ML Use Cases In Manufacturing

by

June 3rd, 2020

Audio Presented by

Trusted software development company since 2009. Custom DS/ML, AR, IoT solutions https://mobidev.biz

About Author

Trusted software development company since 2009. Custom DS/ML, AR, IoT solutions https://mobidev.biz