467 reads

The Steam-Engine Applied to Ship-Propulsion

by

April 18th, 2023

Audio Presented by

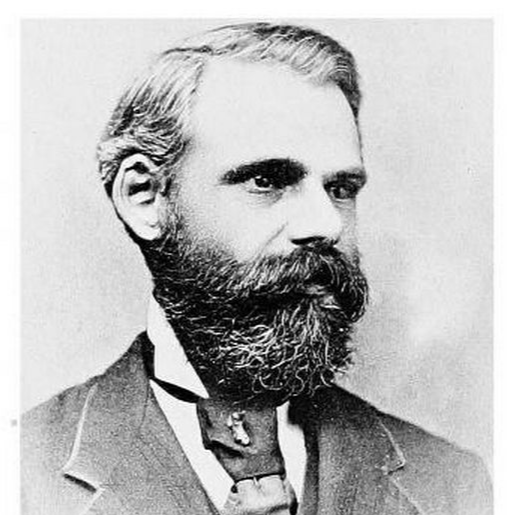

Robert Henry Thurston was an American engineer, and Professor of Mechanical Engineering

About Author

Robert Henry Thurston was an American engineer, and Professor of Mechanical Engineering