Scientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877 by Various, is part of the HackerNoon Books Series. You can jump to any chapter in this book here. BOOT AND SHOE MACHINERY.

BOOT AND SHOE MACHINERY.

No manufacturers have taken greater advantage of the ingenuity of the mechanical engineer than the American boot and shoe makers. Nearly every operation in the complex process of evolving finished boots from the plain skins of leather is the object of a special class of machinery; and for several years past, we have weekly chronicled the patenting of several improvements in the devices for effecting some of the numerous operations. We present herewith a series of eight labor-saving machines of the most approved construction, which we select from Knight's "American Mechanical Dictionary."[1]

Published in numbers by Messrs. Hurd & Houghton, New York city.

Fig. 1 is a shoe-edge trimmer, in which the shoe is mounted on a jack, the carriage of which has a motion of translation and rotation communicated to it: so that, while the side of the sole is being trimmed, the shoe is fed longitudinally against the knife, but at the toe and heel is rotated beneath it. The knife is universally jointed, to permit the hands of the operator to determine the different bevels cut.

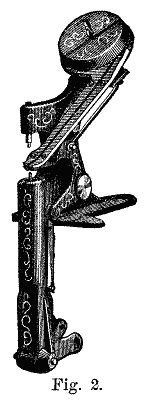

Fig. 2 is an ingenious little machine for placing the eyelets of the lace holes in position, and fastening them. The eyelets are fed, one by one, from the reservoir at the top, down the inclined ways, and are seized at the foot between the plunger and anvil, and they are riveted in their proper places in the shoe or strip of leather, which is held and fed by the operator.

Fig. 4 is a machine for pressing together the "lifts" which compose a boot or shoe heel, thus dispensing with the handiwork of the hammer and lapstone. The bed is adjusted vertically by a screw to any thickness to which the blank heel may be built; and the plunger is brought down by the depression of the treadle with such force as to compact the lifts together.

Fig. 5 shows a heel-pricking machine. When the lifts of the heel are fairly pressed together by the appliance shown in Fig. 4, the pricking machine pierces the necessary holes through all the lifts at once by a gang of awls. The compressed heels are first secured together by tacking, and then placed on the platen; and the plunger, with its gang of awls, descends with great force.

Fig. 5 shows a heel-pricking machine. When the lifts of the heel are fairly pressed together by the appliance shown in Fig. 4, the pricking machine pierces the necessary holes through all the lifts at once by a gang of awls. The compressed heels are first secured together by tacking, and then placed on the platen; and the plunger, with its gang of awls, descends with great force.

Fig. 6 is a heel trimmer, known in the trade as the Coté trimmer. The shoe is held stationary by the treadle clamp; and the knife stock, which is centrally pivoted to the outer plate or jaw bearing upon the tread lift, is then grasped in the hands of the operator, and moved to give a sweeping cut to trim the heel.

Fig. 7 is a machine for pressing boot soles. Beneath the crosshead of the press is a swinging bed, on each end of which is a form, in order that a shoe may remain under pressure upon one while the operator is placing another shoe on the other. The pressure is given by the treadle, which brings down the upper platen on the channeled sole.

About HackerNoon Book Series: We bring you the most important technical, scientific, and insightful public domain books.

This book is part of the public domain. Various (2012). Scientific American, Vol. XXXVII. —No. 2. [New Series.], July 14, 1877. Urbana, Illinois: Project Gutenberg. Retrieved https://www.gutenberg.org/cache/epub/38481/pg38481-images.html

This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org, located at https://www.gutenberg.org/policy/license.html.