203 reads

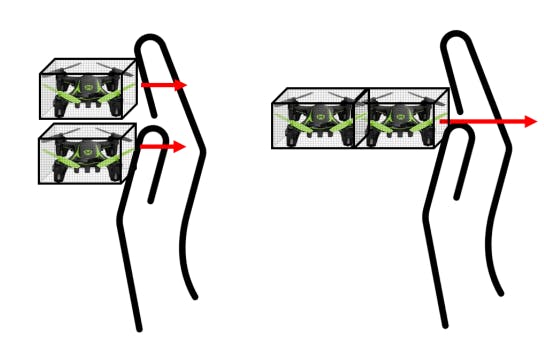

How Flying Light Specks Enable Haptic Interactions

by

July 1st, 2024

Audio Presented by

Pioneering instance management, driving innovative solutions for efficient resource utilization, and enabling a more sus

Story's Credibility

About Author

Pioneering instance management, driving innovative solutions for efficient resource utilization, and enabling a more sus